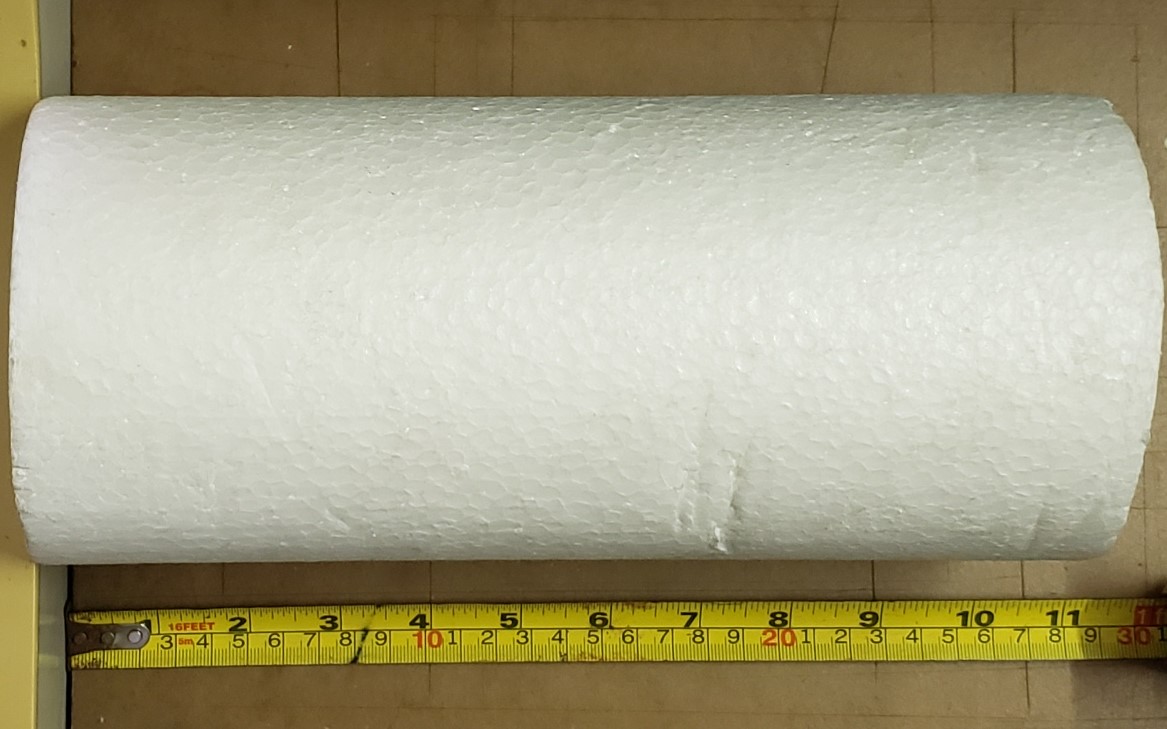

SANBY Polystyrene Foam Board (SPB)

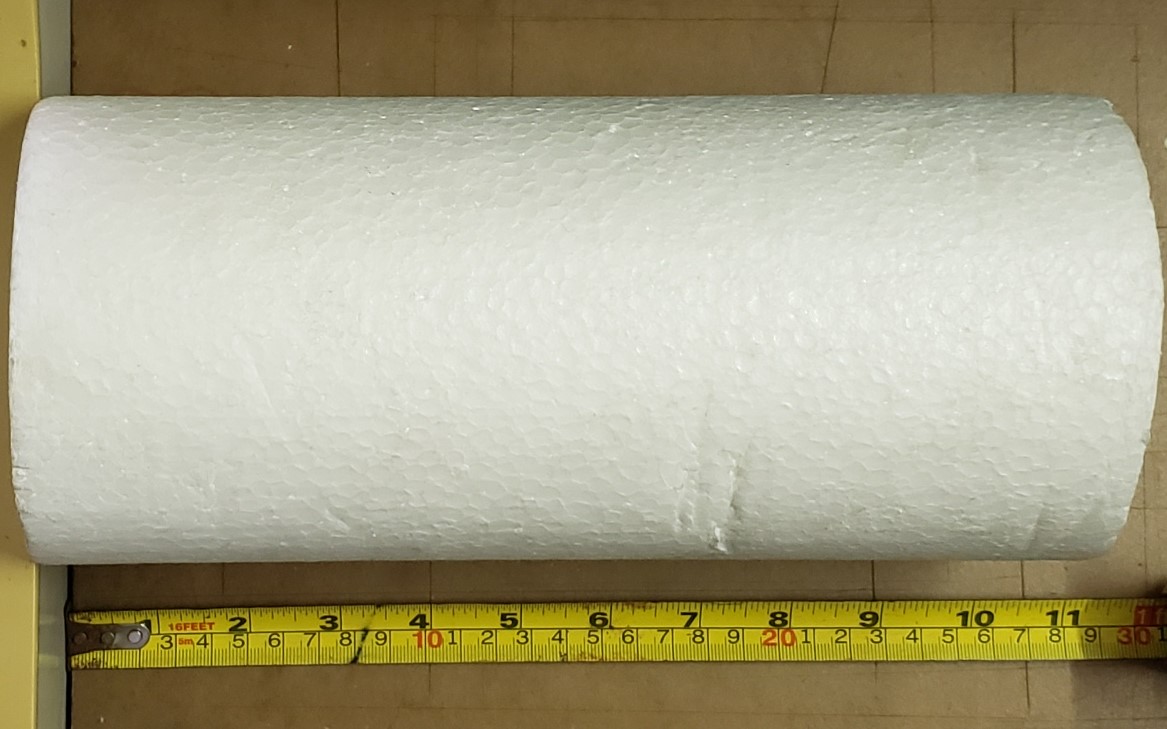

Sanby Polystyrene Foam Board (SPB) is manufactured from cellular polystyrene. The polyfoam is produced by molding of the expanded polymers of polystyrene beads containing a foaming agent and fire-retardant by steam processing within a steel chamber. Pre-expanded polystyrene beads are then aged for 10 – 48 hours before forming blocks.

SANBY provide different modules and lengths: 1M x 2M x 0.5M (Thickness), 36" x 72" x 20"M (Thickness), 48" x 72" x 20" (Thickness), 48" x 96" x 20" (Thickness) by any customer's order.

Application of SANBY Polystyrene Foam Board (SPB)

Constructions

Due to the thermal insulating & sound proof characteristics of the molded polyfoam, SPB is the best building material for the house, theatre, school, rooms & meeting rooms. It is suitable for walls, roofs, and floors; suspend or counter ceiling, insulation panels, etc.

Refrigeration

Insulation of freezing chamber: cold storage rooms in warehouse and trucks.

Air-Conditioning

Insulation and low temperature air ducts; chillers and chilled water pumps.

Packing

Molded polyfoam can be used for the package of foods, electrical appliances and drugs; its low density, strength and elegant outlook will attract customers’ interest and promote sales.

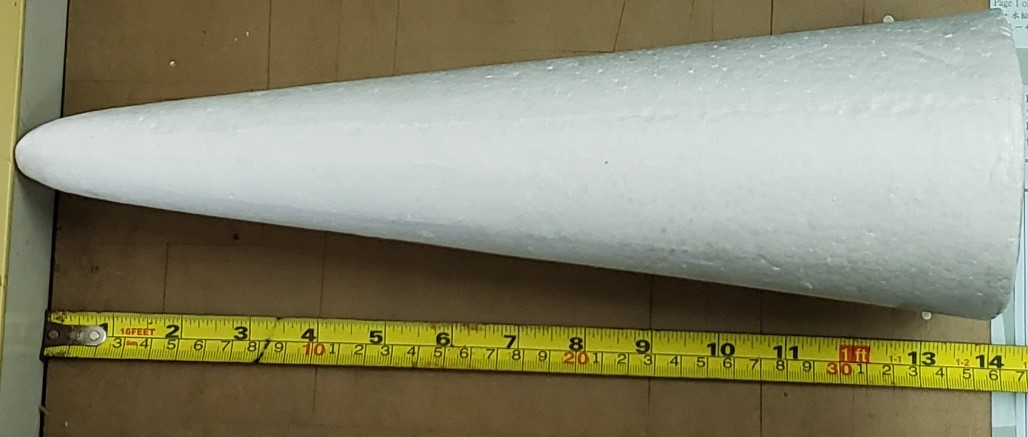

Decoration

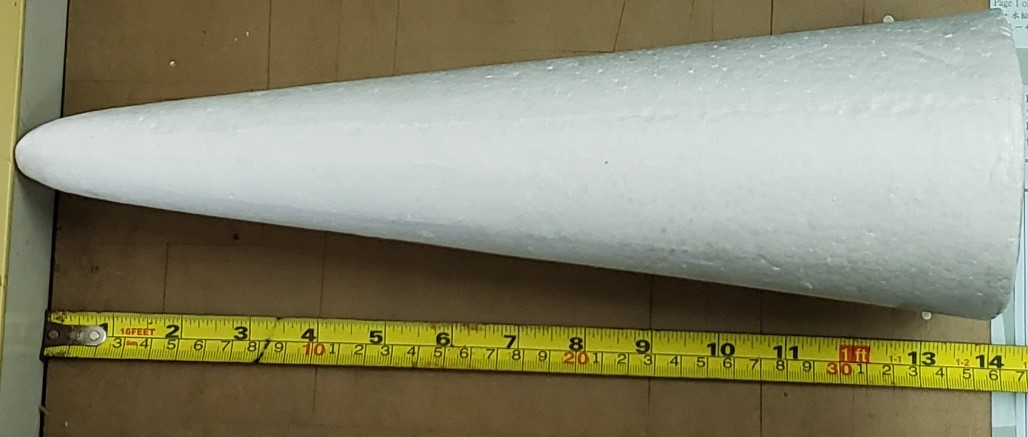

Molded polyfoam have excellent resistance to weather and easy processing, so it is widely used in the decoration of exhibition, stores and picture windows.

Other Usages

Due to its excellent characteristics, molded polyfoam is widely applied in the field of electrical insulators, sandals, flower vase, picture frames, chairs, suitcases and daily appliances, etc.